A comparison study of water disposal methods in a gas project—Part 1

Produced water refers to water associated with the production of oil and/or natural gas from a well. Produced water may also include water produced from a reservoir or water injected into the wellbore to increase the formation pressure for improved hydrocarbon recovery.1,2 The concentration of constituents and the volume of produced water differ dramatically depending on the type and location of the petroleum product.3–5 Generally, the ratio of oil and produced water is 1:3 for most oil wells.6

Produced water quality varies significantly based on geographical location, type of hydrocarbon produced and the geochemistry of the producing formation. In general, the total dissolved solids concentration can range from 100 mg/l to > 400,000 mg/l. Silt and particulates, sodium, bicarbonate and chloride are the most commonly occurring inorganic constituents in produced water. Benzene, toluene, ethylbenzene and xylene (BTEX) compounds are the most commonly occurring organic contaminants in produced water.7–9 The types of contaminants found in produced water and their concentrations have a large impact on the most appropriate type of beneficial use and the degree and cost of the treatment required.10,11

Many different technologies can be used to treat produced water; however, the types of constituents removed by each technology and the degree of removal must be considered to identify potential treatment technologies for a given application.12–16 For some types of produced water, more than one type of treatment technology may be capable of meeting the contaminant removal target, and a set of selection criteria must be applied to narrow down multiple treatment options.17,18

Large water volumes also can cause environmental impacts through erosion, large land area disposal basins, and pipeline and road infrastructure.19 Water-hauling spills and unplanned discharges are all risks when managing produced water.20 The volume of the receiving body is critical in determining environmental impacts: ocean discharge offers substantive dilution, while small streams offer low dilution capacity.21–23 Globally, +/- 250 MMbbl of water are produced daily from both oil and gas fields, and more than 40% are discharged into the environment.24

The most popular option to handle produced water is to reinject it back into the formation. Produced water reinjection requires minimal or modified treatment before injection to obtain better results, but the injectivity decreases with time. As the reservoir matures, injected produced water swipes through to the producing zone and water production increases with time, which causes abandonment of the well. Transportation of produced water from production to injection sites increases reinjection costs.25–28

The main objectives of this study are: to compare water injection into a formation via a disposal well to maintain reservoir pressure of wells, water discharge into the environment (evaporation ponds), trucking of water from the gas project to the neighbor facilities, and installing 4-in. pipeline from the gas project to the neighbor facilities for produced water disposal of the gas project; to select the best method based on technical factors, capital and operating expenditures; and to comply with environmental regulations

GAS PROJECT DESCRIPTION

The gas project will include gas wellhead flowlines and main process facilities to achieve the required gas and condensate export specifications.

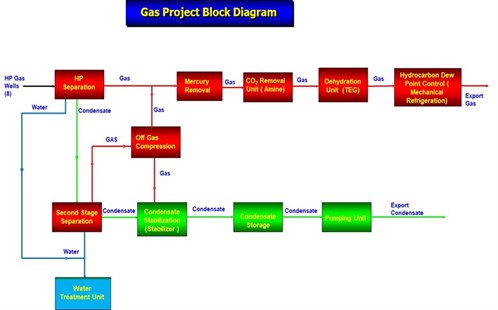

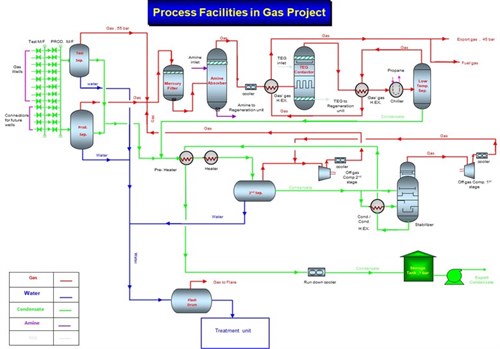

Central process facilities (CPF). FIG. 1 shows the major processing units that make up the CPF, while FIG. 2 details the gas and condensate process facilities in the gas project. The gas project consists of eight wells, a gathering system and CPF, where the production stream from the various fields will be separated into condensate and dew-pointed gas products for export. The gas processing involves inlet facilities for liquid separation, a mercury removal unit, a carbon dioxide (CO2) removal unit, a dehydration unit, and a hydrocarbon dew-pointing unit to meet export gas specifications.

|

|

FIG. 1. Schematic of the CPF process units. |

|

|

FIG. 2 Process facilities in the gas project. |

The condensate separated from the gas in the inlet facilities is stabilized to meet the Reid vapor pressure (RVP) specification for export condensate. The gas will be exported via an export gas pipeline and treated in a dedicated liquefied petroleum gas (LPG) extraction facility to commercial specifications required for end user consumption. The condensate will be exported via an export pipeline to the oil terminal.

Mercury has been detected up to 70 ng/Sm3 in some well samples. Well samples are reported to not contain elemental sulfur, wax and paraffin. Also, the hydrogen sulfide (H2S) content of the wells is zero.

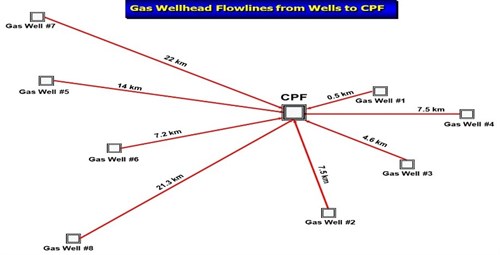

Gas wellhead flowlines. Eight producing wells are initially considered for the gas project. FIG. 3 details the wells and the length for each wellhead flowline. A wellhead pressure of 267 bara, wellhead temperature of 50°C and flowline pressure of 56 bar at the design flowrate of 425,000 m3/d (15 MMft3/d) are used. All eight gas wells have the same design flowrate of 425,000 m3/d. A range of compositions of different condensate gas ratios can be delivered by each gas well, depending on the layer being produced.

|

| FIG. 3. Gas wellhead flowlines from wells to CPF. |

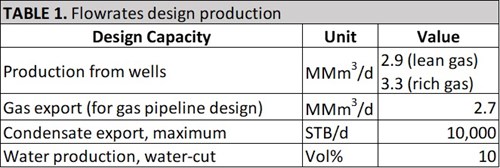

Gas project design capacities. The gas project is designed to produce 2.7 MMm3/d of export gas and 10,000 STB[MR1] /d of export condensate. TABLE 1 displays the design flowrates for the process facilities of the gas project.

|

Export gas specifications. The export gas specifications for gas are: the water dew point is –12°C; the hydrocarbon dew point at 35 barg is 10°C; the CO2 content is < 2% mole; and the pressure of the export gas is 44 barg.

Export condensate specifications. The condensate export specification requires the removal of water and light hydrocarbons to meet the basic sediment and water (BS&W) (< 1% v/v) and RVP (< 0.8 bar and 37.8°C) specifications.

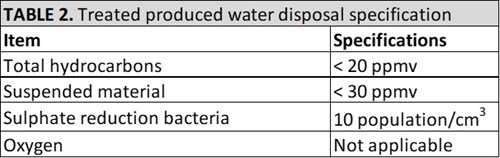

Produced water disposal specification. The produced water volumes increase over the lifetime of the gas well and may reach an assumed maximum of 10% by volume of total liquids for any one gas well. This is based on recommendations received from the reservoir department. The CPF should be designed to handle up to 10% water cut based on fluids from all gas wells. Produced water should be adequately treated before disposal. TABLE 2 illustrates the required treated water disposal specifications for the gas project. The design capacity of the produced water disposal equipment should be 240 m3/d.

|

Produced water disposal options in the gas project: Evaporation ponds. Evaporation ponds are more manageable and suitable to local environment conditions that facilitate evaporation (temperature, wind, availability of land). These ponds must be built and managed according to the requirements of the World Bank environmental, health and safety guidelines for onshore oil and gas development.29

The treated produced water will be routed to an evaporation pond. Due to potential residual contamination by inorganic mercury and miscible liquids (e.g., glycol, amine), lining of the evaporation ponds will be required to prevent water seepage into the ground. The evaporation ponds are to be suitably fenced and netted to prevent wildlife, especially birds, entering the ponds.30,31

The use of a synthetic barrier (e.g., polyethylene, polypropylene) prevents water seepage into the ground and ensures contaminants are retained above ground if the pond is completely evaporated and “dry.” Ponds will be segregated into two sections to enable the isolation of one for maintenance while the other section remains in operation.32

It is recognized, however, that any heavy hydrocarbon residues will become more concentrated in the ponds as water evaporates. Accumulated hydrocarbon residues must be periodically removed from the ponds—no lasting environmental impact will occur due to the presence of hydrocarbon residues.33

It is proposed that the residue after partial evaporation of the produced water can be transported by trucks to the neighbor facilities. Other possible options for disposal of the residue include long-term storage at the site, landfill in a fully lined cell or incineration.

Produced water injection: The use of a water disposal well. The best available technology for produced water disposal is usually considered to require downhole injection. However, it can be uneconomical to drill a well for water disposal for the low initial rates.34

Significant geotechnical investigation is required to determine the depth to which any such well, or wells, must be drilled to avoid risk of contamination of any aquifers in the region.

Downhole injection can also cause groundwater contamination through leaks and cracks in injection well casing, and improperly plugged abandoned oil and gas wells within the radius of influence created by injection wells, and natural or induced fractures, which connect the injection zone with adjacent water zones.

In addition, the compatibility of water in the disposal well formation and the water being injected from the process must be assessed for any potential scaling issues and similar problems.35

Produced water reinjection to production well. Reinjection of produced water into a producing reservoir may be required for reservoir management and has the added advantage of environmental pollution control.36

Reinjection into a depleted well may be considered later in field life, subject to the flowline design conditions and metallurgy being suitable to transport the produced water to the wellsite at an adequate pressure.37

By inspection, pumping of the produced water at high pressure into the ground will use significantly more power than the evaporation ponds option. It represents more risk to the ground water, as mentioned above, and can be costly. It should, however, be noted that if any traces of mercury are found in the well samples at a future date, then this approach should be reassessed.38,39

This method is feasible for higher water cuts or water breakthrough conditions. Based on the cost information available, reinjection into a dedicated water disposal well at the gas project area is a more economical option over a 25-yr period than trucking water to the existing neighbor facilities at water disposal rates greater than 76 m3/d.

Trucking water to existing neighbor facilities—Disposal facilities at existing facilities. At the existing neighbor facilities for the gas project, produced water is drained from the skimmer tank into one of six 100-m3 storage tanks. Here, water is treated prior to being pumped to the saltwater disposal well or evaporation ponds. FIG. 4 shows the produced water settlement and storage tanks in existing neighbor facilities.

|

| FIG. 4. Produced water settlement and storage tanks. |

However, the existing neighbor CPF struggles to deal with the current levels of water [up to 3,000 bpd (~20 m3/hr)], which will increase as the reservoir depletes.

The neighbor CPF sometimes pumps water to the disposal well 24 hr/d and tankers regularly produce water to evaporation pits at the satellite wells, which have been left over from the drilling campaign. Therefore, the capability of the neighbor facilities to handle gas project produced water must be confirmed before this can be adopted as the basis of design.

Trucking water from the gas project. It was envisaged that if required in the early years, produced water from the CPF in the gas project could be taken by tanker and disposed of by injection down the saltwater disposal well at the neighbor CPF.

It is anticipated that the produced water will be drained to the evaporation ponds to take maximum advantage of evaporation as the lowest cost disposal method. If, however, conditions do not allow total evaporation, then removal of the excess water to the neighbor facilities may be necessary.

A hard stand is required at the evaporation ponds at the CPF gas project for a truck to park while water is pumped out of the ponds into the tanker. Additional investment required for this low-cost method of disposal is assumed negligible.

Each truck is assumed to carry up to 20 m3 of water. A third party contracted to transport water between the gas project and neighbor facilities will operate the trucks. One truck movement per hour during daylight hours should be sufficient to dispose of the maximum design quantity of water produced at the CPF of the gas project.

Based on the cost information available, trucking water to the neighbor facilities is the most economical option over a 25-yr period at water disposal rates of less than 17 m3/d. It is also more advantageous than reinjection into a well at the CPF of the gas project at water disposal rates of less than 76 m3/d.

Compatibility with neighbor existing facilities’ formation water. The suitability of injection at neighbor existing facilities as a means of disposal is dependent on the compatibility of the water from the gas project with that produced at neighbor existing facilities.

In early stages of production, the water rates at the CPF of the gas project are expected to be low (i.e., condensing water only) and discharge to an evaporation pond after processing is deemed an acceptable means of disposal. As volumes increase, further tests on compatibility with the neighbor existing facilities can be made and a decision can be made on longer term disposal methods based on improved information.

HSE issues. Regular truck movements between the gas project area and neighbor facilities will greatly increase the risk of accident, as road transportation is a major cause of personal injury and death at any production facility. The effect of regular trucking of water to the neighbor facilities on the gas project risk profile should be reviewed if this is envisaged as the main method of water disposal from the gas project. If, however, this is viewed as a backup to evaporation ponds only when weather conditions do not favor total disposal by evaporation, then the marginal increase in risk may be considered acceptable.

Pipeline to neighbor existing facilities. As an alternative to the trucking of water, construction of a water pipeline from the gas project to the neighbor existing facilities may be considered. Preliminary costing suggests that using a pipeline to the neighbor existing facilities will be more cost-effective than trucking at water rates greater than 173 m3/d, as well as reducing the HSE risk from reduced transport requirements. One of two 100% electric motor drive pumps (one in service; one standing by) will pump water from a holding tank.

A non-metallic pipeline material may be considered [e.g., fiberglass reinforced plastics (FRP) or high-density polyethylene (HDPE)] to avoid corrosion issues. Pipeline length is approximately 60 km with a diameter of 4 in. calculated based on API 14 E standards with a design pressure of ~30 barg. Pigging of the pipeline will not be required.

The neighbor existing facilities are identical to the case where water is trucked between sites. The compatibility of formation water from different sources is an issue also, regardless of whether the water from the CPF of the gas project is trucked or delivered via pipeline. GP

Part 2 of this article will appear in the February issue of Gas Processing & LNG.

LITERATURE CITED

- Kidnay, A. J., W. R. Parrish and D. G. McCartney, Fundamentals of natural gas processing, 3rd Ed., CRC Press, Boca Raton, New York, 2019.

- Noaman, A. A., “Modelling and optimization of the gas and condensate process facilities in the gas plant,” Australian Journal of Basic and Applied Sciences, Vol. 14, No. 12, 2020.

- Gas Processors Suppliers Association, GPSA Engineering Data Book, 14th Ed., Tulsa, Oklahoma, 2017.

- Ferro, B. D. and M. Smith, “Global onshore and offshore water production,” Oil & Gas Review OTC Edition, 2016.

- Bagheri, M., R. Roshandel and J. Shayegan, “Optimal selection of an integrated produced water treatment system in the upstream of oil industry,” Process Safety and Environmental Protection, Vol. 117, 2018.

- Simões, A., R. Macêdo, B. Santos, L. Silva, D. Silva and D. Ruzene, “Produced water: An overview of treatment technologies,” International Journal for Innovation Education and Research, Vol. 8, No. 4, 2020.

- AlAnezi, K., M. Al-Samhan, M. Belkharchouche, W. Abuhaimed, S. Alali, K. Alenizi and A. Alfuraij, “Comparative analysis of produced water collected from different oil gathering centers in Kuwait,” Journal of Environmental Protection, Vol. 9, 2018.

- Taghavinejad, A., S. Shafeie and A. Shirbazo, “Analysis of wastewater disposal in depleted tight gas reservoirs: A sustainable resources approach,” Journal of Construction Materials, Special Issue, 2021.

- U.S. Environmental Protection Agency (EPA), “Oil and gas extraction effluent guidelines,” Washington DC, 2019.

- Al-Ghouti, M. A., M. A. Al-Kaabi, M. Y. Ashfaq and D. A. Da´na, “Produced water characteristics, treatment and reuse: A review,” Journal of Water Process Engineering, Vol. 28, 2019.

- Menefee, A. H. and B. R. Ellis, “Wastewater management strategies for sustained shale gas production, Environmental Research Letters, IOP Publishing Ltd., January 2020.

- Xinchao, W., Z. Shicheng, H. Yuexin and A. Frederick, “Treatment of petrochemical wastewater and produced water from oil and gas,” Water Environment Research, Vol. 91, No. 10, 2019.

- Ebrahiem, E. E., A. A. Noaman, M. I. Mansour and M. S. Almutairi, “Produced water treatment design methods in the gas plant: Optimization and controlling,” Egyptian Journal of Chemistry, Vol. 64, No. 7, 2021.

- Fulazzaky, M., T. Setiadi and M. A. Fulazzaky, “An evaluation of the oilfield-produced water treatment by the membrane bioreactor,” Journal of Environmental Chemical Engineering, Vol. 8, Iss. 5, 2020.

- Bagheri, M., R. Roshandel and J. Shayegan, “Optimal selection of an integrated produced water treatment system in the upstream of oil industry,” Process Safety and Environmental Protection, Vol. 117, July 2018.

- Ersahin, M. E., H. Ozgun, R. Kaya, B. K. Mutlu, C. Kinaci and I. Koyuncu, “Treatment of produced water originated from oil and gas production wells: A pilot study and cost analysis,” Environmental Science and Pollution Research, Vol. 25, No. 7, 2018.

- Olajire, A. A., “Recent advances on the treatment technology of oil and gas produced water for sustainable energy industry-mechanistic aspects and process chemistry perspectives, Chemical Engineering Journal Advances, Vol. 4, December 2020.

- Manilal, A. M., P. A. Soloman and C. A. Basha, “Removal of oil and grease from produced water using electrocoagulation,” Journal of Hazardous, Toxic, and Radioactive Waste, Vol. 24, No. 1, 2020.

- Gazali, A. K., A. N. Alkali, Y. Mohammed, Y. Djauro, D. D. Muhammed and M. kodomi, “Environmental impact of produced water and drilling waste discharges from the Niger Delta petroleum industry,” IOSR Journal of Engineering, Vol. 07, No. 6, June 2017.

- Varjani, S., R. Joshi, V. K. Srivastava, H. H. Ngo and W. Guo, “Treatment of wastewater from petroleum industry: Current practices and perspectives, Environmental Science and Pollution Research, Vol. 22, 2020.

- Rasheed, T., M. Bilal, F. Nabeel, M. Adeel and H. M. Iqbal, “Environmentally-related contaminants of high concern: Potential sources and analytical modalities for detection, quantification, and treatment,” Environmental International, Vol. 122, 2019.

- Echchelh, A., T. Hess and R. Sakrabani, “Agro-environmental sustainability and financial cost of reusing gas field-produced water for agricultural irrigation,” Agricultural Water Management, Vol. 227, 2020.

- Hedar, Y. and Budiyono, “Pollution impact and alternative treatment for produced water,” E3S Web of Conferences, The 2nd International Conference on Energy, Environmental and Information System, Vol. 31, February 2018.

- Wei, X., S. Zhang, Y. Han and F. A. Wolfe, “Treatment of petrochemical wastewater and produced water from oil and gas,” Water Environment Research, Vol. 91, 2019.

- Al-Taq, A. A., M. N. Al-Dahlan and A. A. Alrustum, “Maintaining injectivity of disposal wells: From water quality to formation permeability,” SPE Middle East Oil & Gas Show and Conference, Manama, Kingdom of Bahrain, March 2017.

- Sahu, P., “A comprehensive review of saline effluent disposal and treatment: Conventional practices, emerging technologies, and future potential,” Journal of Water Reuse and Desalination, Vol. 11, No. 1, 2021.

- U.S. Environmental Protection Agency (EPA), “General information about injection wells,” Washington DC, 2016.

- Hasan, M., M. M. Rahman and M. Ahmed, “A short review of produced water management system for beneficial use,” American Journal of Agricultural Science, Engineering and Technology, Vol. 5, Iss. 1, 2021.

- Ahmed, Q. A., H. B. Nimir, M. A. Hussien, M. M. Zomrawi, E. M. Babiker and I. Fadul, “Evaluation of seepage from evaporation ponds of produced water in some Sudanese oilfields,” 2nd Conference of Civil Engineering, Sudan, 2018.

- Bangash, A., M. Ghayur and N. Khattak, “Evaluation and analysis of forced evaporation system for oil & gas production facilities in Pakistan,” International Journal of Innovative Science, Engineering & Technology, Vol. 2, No. 12, 2015.

- McLaughlin, M. C., T. Borch, B. McDevitt, N. R. Warner and J. Blotevogel, “Water quality assessment downstream of oil and gas produced water discharges intended for beneficial reuse in arid regions,” Science of The Total Environment, Vol. 713, 2020.

- Gray, M., “Reuse of produced water in the oil and gas industry,” SPE International Conference and Exhibition on Health, Safety, Environment, and Sustainability, Virtual, July 2020.

- Ilyas, M., F. M. Kassa and M. R. Darun, “A proposed framework of life cycle cost analysis for petrochemical wastewater treatment plants,” International Conference on Civil, Offshore and Environmental Engineering, Springer, Singapore, 2021.

- Mohammed, T. J. and J. M. Jasim, “Treatment of wastewater associated with crude oil in reservoirs,” Journal of Petroleum Research and Studies, Vol. 6, 2019.

- Siagian, U. W. R., S. Widodo, Khoiruddin, A. K. Wardani and I. G. Wenten, “Oilfield produced water reuse and reinjection with membrane,” MATEC Web of Conferences Vol. 156, 2018.

- Feder, J., “Saltwater disposal optimization drives water midstream sector,” Journal of Petroleum Technology, Vol. 72, No. 11, 2020.

- Al Qallaf, Y., S. Al-Kandari, K. Yousef, S. Al Mutairi and H. Fouzy, “Analysis and improvement possibilities of waste management at Kuwait Oil Company (KOC),” WIT Transactions on Ecology and the Environment, Vol. 202, 2016.

- Helaly, R., A. Bekheit, M. Farahaty and M. Tawfik, “Overcoming the typical operational problems & cost of water injection using dumpflooding,” North Africa Technical Conference & Exhibition, Cairo, Egypt, 2013.

- Kassab, M. A., A. E. Abbas, I. Elgamal, B. M. Shawky, M. F. Mubarak and R. Hosny, “Review on the estimating the effective way for managing the produced water: Case study,” Open Journal of Modern Hydrology, Vol. 11, 2021.

ABDELAZIZ NOAMAN is on the Faculty of Engineering within the Chemical Engineering Department at Minia University. He earned a PhD in chemical engineering from Minia University, Egypt in 2018 in the field of process and flow assurance engineering. Dr. Noaman is interested in the environment, water and wastewater treatment, corrosion, operations in oil and gas facilities, and pipeline networks. He has an extensive experience in using various process software, such as HYSYS, PIPESIM, OLGA, Flaresim, Gap and Pipe phase, and is keen on simulation of all oil and gas facilities and pipeline networks. Dr. Noaman is a Charter Engineer from the UK Engineering Council, a Consultant Engineer from the Egyptian syndicate of engineers, a European Engineer by the European Federation of National Associations and an International Professional Engineer by the UK Engineering Council. The author can be reached at abdelaziz.noaman@outlook.com.

Comments