Fire water pump “listed” flexible shaft couplings procurement challenges

As part of the detailed design stage of a gas processing project (Jafurah Gas Plant) for the author’s company, the assigned contractor is in control to start the bidding process with approved vendors to procure needed equipment. Fire water pumps are some of the most critical equipment in such a project, as they play a major role in safety. As part of international standards, certain conditions and requirements should be followed. The author’s company is well-known for its high safety measures for all of its industrial and commercial facilities.

The Saudi Aramco Project Management Team (SAPMT) faced challenges procuring the listed couplings for the main fire water pumps, as defined by NFPA 20 under Clause 3.2.3.1 This article introduces these challenges and the proposed solutions.

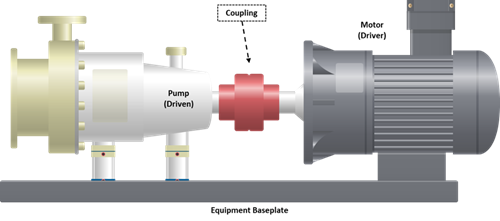

Background. Couplings are considered to be the most critical component that connect the driver (motor or diesel engine) to the driven equipment (pump or compressor) to transfer power. FIG. 1 shows the location of a coupling and how they are installed.

As part of the detailed design stage of the Jafurah Gas Plant Project, all equipment undergo a detailed review with vendors to identify all deviations and clarifications before moving to the next stage of the project. The main fire water pumps play a major role and are the main pillars of ensuring safety and reliability of the plant. A total of six fire water pumps are divided as shown below:

- Two fire water jockey pumps

- Two fire water pumps (450-hp electric motor-driven, 3,000 gpm)

- Two fire water pumps (510-hp diesel engine-driven, 3,000 gpm)

As per the company’s standards, the main fire water pumps shall comply with National Fire Protection Association (NFPA) standards. Clause 6.5.1.2 of NFPA 20 (2022 Ed.) mandates that a flexible coupling is to be listed.

Listed couplings are designed to ensure the safety and reliability of the equipment. Two safety organizations standardize listing requirements: Underwriters Laboratories (UL) and Factory Mutual Laboratories (FM). Having a listed coupling means that such components or equipment were tested by such organizations and can be labeled as “listed.”

Analysis. The SAPMT conducted a detailed exercise to determine whether any listed couplings in the marketplace were available for the main fire water pumps. For main fire water pumps driven by electric motors, flexible couplings must be sourced from a regulated vendor list (RVL). Conversely, flexible couplings for fire water pumps driven by diesel engines do not need to be sourced from an RVL.

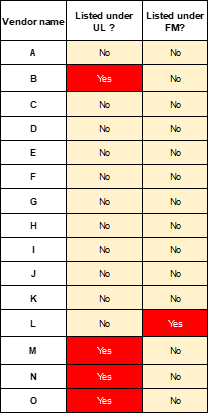

During the project proposal stage of this project, the fire water pumps were designed with a brake horsepower of more than 430 hp. Therefore, finding a UL/FM listed coupling for the main fire water pumps was not possible. TABLE 1 shows a summary of the exercise conducted by the SAMPT to find UL/FM listed couplings for the main fire water pumps.

|

| TABLE 1. A summary of the exercise conducted by the SAPMT |

As shown in TABLE 1, there are only four UL listed vendors and one FM listed vendor. For UL listed vendors, most of them cannot provide UL listed couplings for motors with more than 430 hp. Some of the UL and FM listed vendors do not support other pump companies and provide full packages (including bare pump, coupling and driver).

As there was a signed agreement between the company and the pump vendor before the detailed design stage, the contractor was not allowed to bid with other vendors unless such vendors cannot comply with the company’s standards and specifications. Therefore, using an FM approved vendor can incur a significant delay to the project.

Alternative solution. There is an alternative solution that, if implemented, enables listed couplings to be secured for all main fire water pumps. However, this option has several impacts. The alternative options below were carefully studied:

- Option A: To provide non-listed couplings for the main fire water pumps. However, these couplings must meet all technical requirements set by Aramco’s Consulting Services Department to ensure the safety and reliability of the main fire water pumps.

- Option B: To change the design concept of fire water pumping system. This will result in increasing the number of pumps from two sets to three sets of 2,000-gpm pumps, which will reduce the driver horsepower of the electric motor from 430 hp to 330 hp, and the diesel engine from 540 hp to 400 hp. This will ensure the availability of listed couplings for the main fire water pumps. However, this option will result in additional significant cost impacts, and a delay of more than 9 mos, as this option would require a re-design of the entire fire water pumping system.

Final selection and takeaways. After several meetings between the SAPMT and the company’s standard chairperson, the path forward is summarized below:

- Fire water pumps (diesel engine-driven): The couplings will be provided by a vendor that previously provided several diesel engines to the company. The coupling will be non-UL listed. However, the vendor has provided an official letter stating that the coupling meets the intent of the UL certification and as per UL 448A the coupling has a service factor of 1.5 of the six-cylinder diesel engine power rating.2

- Fire water pumps (electric motor-driven): The final selection for electric motor-driven fire water pump coupling will be non-UL listed with the below requirements:

- The coupling is a fail-safe design that will transmits power even after the element fails. This is in line with UL 448A section 9.1.

- The coupling service factor is not less than the value specified in UL 448A, which is 1.

- The flexible coupling is sized based on the rating of the driver and not the pump, which should align with UL 448A section 17.1 d. This calculation/sizing shall include the adjustment of the service factor.

Additional requirements were recommended to increase the reliability of the provided couplings include:

- Increase the coupling distance between shaft ends (DBSE) from 5.1 in. to 10 in.

- Ensure the coupling bolts are from hardened stainless-steel material.

Option A was considered to ensure equipment is delivered on time and to avoid schedule impact. GP

LITERATURE CITED

- National Fire Protection Association (NFPA) 20, “Standard for the installation of stationary pumps for fire protection,” 2016.

- Underwriters Laboratories UL 448A, “Flexible couplings and connecting shafts for stationary fire pumps,” September 2022.

Wesam Khalaf Allah is a rotating equipment Senior Engineer with 11 yr of experience at Saudi Aramco, specializing in pumps and mechanical seals.

Comments