Høglund awarded automation contracts for LNG, chemical tanker

Høglund Marine Automation announced the company has secured contracts to supply automation systems for an LNG bunker vessel operated by Bernhard Schulte, and two chemical tankers for Sirius Shipping.

|

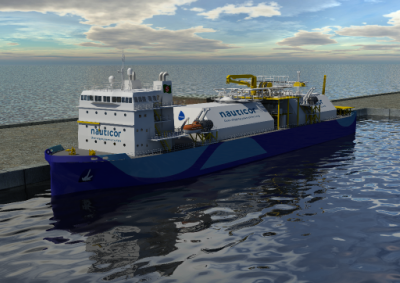

| Photo Courtesy of Høglund Marine Automation. |

Both projects require Høglund to work in partnership with its customers, shipyards and naval architects to devise new solutions to address complex automation challenges. Bernhard Schulte’s LNG bunkering vessel, which will be built at Hyundai Mipo Dockyard, is one of only a few of its kind so far.

This places unique requirements on the automation systems Høglund will provide, which include the vessel’s power management system, and additional systems that manage interactions between the ship machinery systems, and the cargo plant. While LNG carriers have been in service for many years, and use boil-off gas to burn in their engines, bunkering barges must extract vapor from receiving ships to use as fuel. This requires additional interfaces between the gas plant and the rest of the ship, drastically increasing the complexity of the automation.

Of a small number of LNG bunkering vessels that currently exist, Høglund automation solutions are present on three of them, including Shell’s specialized LNG bunkering vessel now being built at STX in Korea, and the Seagas, a bunkering vessel owned by AGA and operated by Sirius, that has completed around 1200 bunkering operations.

Similarly, Sirius Shipping’s chemical tankers, to be built at the AVIC Ding Heng yards in China, will use integrated automation systems developed by Høglund. The integration will for instance link the power management systems to the cargo system. While the two systems are usually separate, integrating the two means that offloading operations will be more efficient, and require fewer generators to operate.

“When creating automation solutions for an entirely new vessel sub-segment within LNG, it’s hard to predict and foresee what challenges might emerge, which means you can’t just use an off the shelf solution,” said Børge Nogva, CEO of Høglund Marine Automation. “By playing a consultative role throughout the design and build stages, and supporting vessels 24/7 once they begin operation, automation suppliers can deliver significant benefits in terms of reliability and efficiency, as these projects demonstrate.”

In addition to the automation systems on board, Høglund also supports automation systems with remote access, allowing its engineers to resolve automation issues remotely.

- RWE strengthens partnerships with ADNOC and Masdar to enhance energy security in Germany and Europe

- TotalEnergies and Mozambique announce the full restart of the $20-B Mozambique LNG project

- Five energy market trends to track in 2026, the year of the glut

- Venture Global wins LNG arbitration case brought by Spain's Repsol

- Trinity Gas Storage reaches FID on Phase II expansion

Comments